- Home Page

- Company Profile

-

Our Products

- Instrumentation products

- Material Testing & System

- Stress Corrosion Cracking Testing Machine

- Impression Creep Testing Machine

- Low Velocity Drop Tower Impact Testing Machine

- Advanced Impression Creep Testing Machine

- ROTATING BENDING FATIGUE TESTING MACHINE

- Uni Axial Fatigue Testing Machine

- Constant Load Stress Corrosion Cracking Test Setup

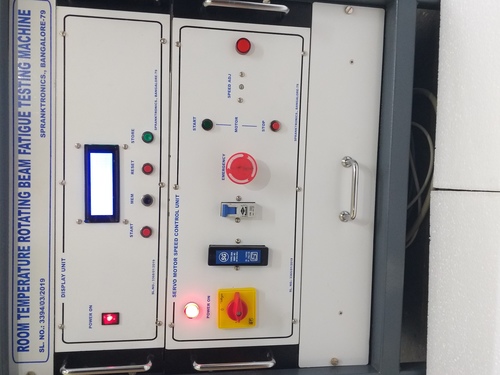

- Rotating Bending Fatigue Testing machine controller

- High Temperature & Room Temperature Rotating Bending Fatigue Testing Machine

- Vibration Measurements & Analysis

- Sensors & Data Acquisition Systems

- Transportation & Structural Engg. Lab. Equipment

- Soil Fatigue testing Machine

- Material Testing Machines

- Contact Us

Uni Axial Fatigue Testing Machine

Product Details:

- Resistant Feature Corrosion Resistant Surface

- Batteries Type Not Required (Mains Powered)

- Pressure Upto 10 kN Load Capacity

- Accuracy 1% of Indicated Value

- Usage & Applications Determination of material fatigue under uni-axial loading in labs, research, and QA testing

- Product Type Uni Axial Fatigue Testing Machine

- Material Heavy Duty Steel Alloy

X

Uni Axial Fatigue Testing Machine Price And Quantity

- 1 Set

- 220-240 V AC, 50 Hz

- Up to 100 mm stroke

- Room Temperature Operation

- User Manual, Software CD, Extra Jaws

- Digital Microprocessor Based Control

- Emergency Stop, Protective Enclosure

- PC Interface with Dedicated Software

- 0.1 to 50 Hz (adjustable frequency)

- Cyclic Loading, Tensile/Compression Fatigue

- Onsite Setup and Training Available

- Up to 12 mm

- Interchangeable Grips for Various Specimens

- Digital LCD Display for Parameters

Uni Axial Fatigue Testing Machine Product Specifications

- Not Required (Mains Powered)

- Standard Laboratory Size

- Approx. 400 kg

- Uni Axial Fatigue Testing Machine

- Corrosion Resistant Surface

- Approx. 1000 x 600 x 1500 mm

- Overload Protection System Included

- Blue and White

- 220-240 V AC

- Upto 10 kN Load Capacity

- 1% of Indicated Value

- 10C to 40C

- Determination of material fatigue under uni-axial loading in labs, research, and QA testing

- Heavy Duty Steel Alloy

- 50-60 Hz

- 220-240 V AC, 50 Hz

- Up to 100 mm stroke

- Room Temperature Operation

- User Manual, Software CD, Extra Jaws

- Digital Microprocessor Based Control

- Emergency Stop, Protective Enclosure

- PC Interface with Dedicated Software

- 0.1 to 50 Hz (adjustable frequency)

- Cyclic Loading, Tensile/Compression Fatigue

- Onsite Setup and Training Available

- Up to 12 mm

- Interchangeable Grips for Various Specimens

- Digital LCD Display for Parameters

Uni Axial Fatigue Testing Machine Trade Information

- 5 Set Per Month

- 2 Week

Product Description

Uni-Axial & Multi Axial Fatigue Testing Machine

| Axial Load Capacity | 2 Tonne(Dynamic 1-3hz, Tension Tension, Sine Wave, Static Tensile Tests) |

| Torque | +/-100 Nm |

| Angle | +/- 10 Deg C |

| Control | Servo Hydraulics |

| Feed back controls | Load, Torque and Angle |

| Specimen | Standard dog bone tensile test specimen, Thickness 2mm to 6mm |

| Gripper | Mechanical wedge gripper for flat and round specimen, Flat 2mm to 6mm, Round- 4mm to 8mm |

| Hydraulic Power Pack | Capacity to drive 2T parallel 2 Pumps for 2 Actuators |

Precise Digital Control and Data Acquisition

Featuring a digital microprocessor-based control system, this machine ensures accurate and repeatable fatigue testing. Data collection is streamlined through a PC interface and dedicated software, enabling detailed test analysis and effortless report generation for researchers and quality assurance professionals.

Versatile and Flexible Test Capabilities

With support for both tensile and compression fatigue testing, adjustable frequency up to 50 Hz, and stroke lengths up to 100 mm, the machine caters to a diverse range of specimens and applications. Interchangeable grips accommodate various sample shapes and sizes, offering great adaptability for different test requirements.

Safety, Durability, and Ease of Use

Built from a heavy-duty steel alloy and coated with a corrosion-resistant finish, the apparatus combines durability with a user-centric design. Sectioned with comprehensive protective featuressuch as emergency stop, overload protection, and a secure enclosureusers can operate the machine with confidence, bolstered by onsite installation support and accessible operation manuals.

FAQs of Uni Axial Fatigue Testing Machine:

Q: How does the digital microprocessor-based controller enhance fatigue testing accuracy?

A: The digital microprocessor-based controller ensures precise control over test parameters such as load, frequency, and stroke, minimizing human error and promoting reliable, repeatable results under cyclic loading conditions.Q: What specimen diameters and load capacities does this fatigue testing machine support?

A: The machine can accommodate specimens of up to 12 mm diameter and is capable of applying loads up to 10 kN, making it versatile for a wide range of material types and shapes.Q: When is cyclic loading fatigue testing recommended, and what benefits does it offer?

A: Cyclic loading fatigue tests are essential during material development, quality assurance, and research stages to assess how materials withstand repeated stress. This informs product design and predicts potential material failures.Q: Where can the Uni Axial Fatigue Testing Machine be installed, and is support provided?

A: The machine is designed for standard laboratory environments and operates within room temperature (10C to 40C). Onsite setup and training support are available across India to ensure proper installation and usage.Q: What is the process for running a fatigue test using this equipment?

A: After specimen preparation, mount the sample using the appropriate interchangeable grips, set the desired test parameters via the digital interface, and initiate the test. Data are acquired in real-time and analyzed through the dedicated PC software.Q: What safety and protection features are integrated into the machine?

A: For user safety and equipment protection, the machine includes an emergency stop button, overload protection, and a secure protective enclosure that shields operators from potential hazards during testing.Q: What are the main benefits of using this machine for research and quality assurance applications?

A: The system delivers precise, efficient, and reproducible fatigue test results, enabling researchers and engineers to evaluate material durability and performance accurately, ultimately supporting informed material selection and quality control processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese