- Home Page

- Company Profile

-

Our Products

- Instrumentation products

- Material Testing & System

- Stress Corrosion Cracking Testing Machine

- Impression Creep Testing Machine

- Low Velocity Drop Tower Impact Testing Machine

- Advanced Impression Creep Testing Machine

- ROTATING BENDING FATIGUE TESTING MACHINE

- Uni Axial Fatigue Testing Machine

- Constant Load Stress Corrosion Cracking Test Setup

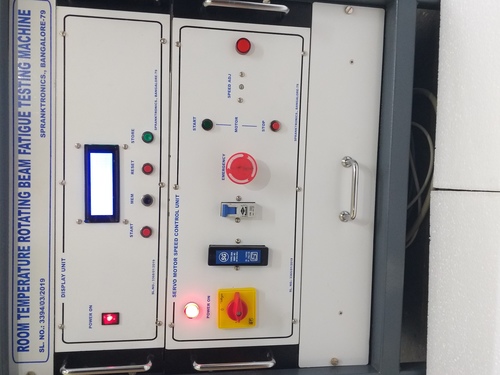

- Rotating Bending Fatigue Testing machine controller

- High Temperature & Room Temperature Rotating Bending Fatigue Testing Machine

- Vibration Measurements & Analysis

- Sensors & Data Acquisition Systems

- Transportation & Structural Engg. Lab. Equipment

- Soil Fatigue testing Machine

- Material Testing Machines

- Contact Us

ROTATING BENDING FATIGUE TESTING MACHINE

Product Details:

- Usage & Applications Determination of fatigue strength of metals and alloys under rotating bending stress

- Accuracy 1% of reading

- Resistant Feature Corrosion resistant coated body

- Product Type Rotating Bending Fatigue Testing Machine

- Material Mild steel body with anti-corrosive finish

- Operating Temperature 10C to 40C (ambient laboratory conditions)

- Protection System Enclosed safety guard over rotating components

X

ROTATING BENDING FATIGUE TESTING MACHINE Price And Quantity

- 1 , , Set

- 6 - 60 Nm (Newton metre)

- 110 mm

- 4200 ± 200 RPM (revolutions per minute)

- 0.5 HP single phase motor

- 230V AC, 50 Hz

- Automatic stop and indication at specimen failure

- Digital counter for number of revolutions

- Maximum up to 12 mm

- Variable loading through calibrated weights

ROTATING BENDING FATIGUE TESTING MACHINE Product Specifications

- Approx. 870 mm x 400 mm x 560 mm

- 10C to 40C (ambient laboratory conditions)

- Approx. 100 kg

- Compact, suitable for laboratory benchtop installation

- Industrial Grey & Blue

- Mild steel body with anti-corrosive finish

- 1% of reading

- Rotating Bending Fatigue Testing Machine

- Determination of fatigue strength of metals and alloys under rotating bending stress

- Corrosion resistant coated body

- Enclosed safety guard over rotating components

- 6 - 60 Nm (Newton metre)

- 110 mm

- 4200 ± 200 RPM (revolutions per minute)

- 0.5 HP single phase motor

- 230V AC, 50 Hz

- Automatic stop and indication at specimen failure

- Digital counter for number of revolutions

- Maximum up to 12 mm

- Variable loading through calibrated weights

ROTATING BENDING FATIGUE TESTING MACHINE Trade Information

- 5 , , Set Per Month

- 2 Week

Product Description

Details

- BENDING MOMENT CAPACITY: 0 10 nm, Least count 0.02 nm

- ROTATIONAL SPEED: 1000 TO 3000 RPM

- CYCLE COUNTING CAPACITY: 10 pow7 Cycles

- Speed Sensor: Proximity pickup

- SPECIMEN: Cylindrical, 7 mm Gripping Dia, Length 60 mm,gauge length 20 mm, Gripping Depth 20 mm

Precise Fatigue Testing for Metals and Alloys

This fatigue testing machine delivers consistent results for determining the endurance of metals and alloys under controlled rotating bending conditions. Equipped with a digital counter and variable loading fixtures, it ensures users can accurately monitor cycles and loading, vital for material research and quality assurance.

User-Friendly and Safe Laboratory Design

The compact machine fits easily on laboratory benchtops and features an enclosed safety guard, protecting users from rotating parts during operation. Its anti-corrosive finish enhances longevity, making it a robust investment for manufacturers and educational institutions alike.

FAQs of ROTATING BENDING FATIGUE TESTING MACHINE:

Q: How does the Rotating Bending Fatigue Testing Machine detect specimen failure?

A: The machine features an automatic stop mechanism that immediately halts operation and provides a clear indication when the specimen fails, ensuring timely and safe test completion.Q: What is the process for setting up and conducting a fatigue test using this machine?

A: Simply secure your specimen (up to 12 mm in diameter and 110 mm in length), set the desired bending moment using calibrated weights, and start the machine. The digital counter records the number of revolutions until failure is detected.Q: Where is this testing machine typically used?

A: This equipment is commonly utilized in research laboratories, educational institutions, and industrial quality control departments across India for analyzing fatigue properties of metals and alloys.Q: When should I use this machine for material testing?

A: Use the Rotating Bending Fatigue Testing Machine when you need to determine the fatigue strength of metal samples under repetitive bending stress, particularly for product development, academic research, or quality assessment.Q: What benefits does the digital display provide during testing?

A: The digital counter offers real-time recording of the number of revolutions, allowing for precise data collection and facilitating accurate calculation of fatigue strength for each material tested.Q: How does the machine ensure operator safety?

A: It includes an enclosed safety guard over all rotating components, protecting users from accidental contact and contributing to a secure laboratory environment.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese