- Home Page

- Company Profile

-

Our Products

- Instrumentation products

- Material Testing & System

- Stress Corrosion Cracking Testing Machine

- Impression Creep Testing Machine

- Low Velocity Drop Tower Impact Testing Machine

- Advanced Impression Creep Testing Machine

- ROTATING BENDING FATIGUE TESTING MACHINE

- Uni Axial Fatigue Testing Machine

- Constant Load Stress Corrosion Cracking Test Setup

- Rotating Bending Fatigue Testing machine controller

- High Temperature & Room Temperature Rotating Bending Fatigue Testing Machine

- Vibration Measurements & Analysis

- Sensors & Data Acquisition Systems

- Transportation & Structural Engg. Lab. Equipment

- Bitumen Indirect tensile testing machine

- Soil Fatigue testing Machine

- Transportation

- Soil mechanics

- Structural

- Geo Technical

- Material Testing Machines

- Contact Us

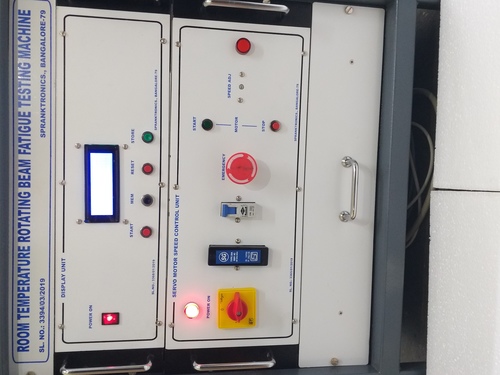

Rotating Bending Fatigue Testing machine controller

Product Details:

- Batteries Type Not required, main powered

- Accuracy 0.5%

- Usage & Applications Used to control and monitor fatigue testing cycles in rotating bending fatigue testing machines

- Resistant Feature Corrosion resistant and impact-resistant

- Product Type Rotating Bending Fatigue Testing Machine Controller

- Material Industrial Grade Steel and ABS Housing

- Measuring Voltage Range 0-10V DC

X

Rotating Bending Fatigue Testing machine controller Price And Quantity

Rotating Bending Fatigue Testing machine controller Product Specifications

- Industrial Grade Steel and ABS Housing

- 4.5 kg

- Rotating Bending Fatigue Testing Machine Controller

- Used to control and monitor fatigue testing cycles in rotating bending fatigue testing machines

- 0.5%

- Metallic Grey with Black Panel

- 0-10V DC

- Not required, main powered

- 320 mm x 210 mm x 100 mm

- Corrosion resistant and impact-resistant

- 0C to 50C

- Standard compatible with most fatigue testing machines

- 0.1 - 5 MHz

- Enclosed for safety and thermal insulation

- Overload and short-circuit protection

Rotating Bending Fatigue Testing machine controller Trade Information

- Per Year

- Days

Product Description

We are considered as one of the leading manufacturers and suppliers of Rotating Bending fatigue testing Machine and Controller that is made available in diverse technical specifications. Manufactured by utilizing finest quality components in adherence with set industry norms, this machine is highly admired among our customers owing to its hassle free performance and excellent functionality. As the name implies, it is used for controlling rotation beam machine. Moreover, we provide this Rotating Beam Machine Controller at pocket friendly prices to the clients.

Features:

- Sturdy design

- Low maintenance

- Power efficient

- Trouble free performance

Effortless Cycle Control and Monitoring

This fatigue testing machine controller offers high precision and excellent reliability in managing rotating bending fatigue tests. Its digital LCD and tactile interface simplify setup and monitoring, while the built-in alarm system ensures each test completes safely. The robust construction and enclosed safety features make it ideal for demanding laboratory or manufacturing use.

Advanced Data Handling and Export

Equipped with internal memory and export options via USB and RS232 ports, the controller enables comprehensive data logging. Users can efficiently transfer test results for detailed analysis or records, streamlining quality assurance and research processes. The large cycle counter capacity is perfect for extended test scenarios.

Safety, Compliance, and Durability

Designed with an insulated enclosure and overload protection, this controller guarantees operational safety. It meets CE and ISO standards while offering corrosion and impact resistance, making it suitable for rigorous industrial settings and long-term use. Its compatibility with standard fatigue testing machines assures seamless integration.

FAQs of Rotating Bending Fatigue Testing machine controller:

Q: How do I operate the fatigue testing machine controller?

A: To operate the controller, use the touch keypad and rotary selector to configure test parameters. The digital LCD guides you through cycle counts, voltage settings, and alarm configurations. Once set up, the machine automatically sequences cycles and provides real-time test data.Q: What is the process for exporting test data from the controller?

A: Test results are stored in the controllers internal memory and can be exported via USB or RS232 ports. Simply connect your storage device or PC, select the desired data set on the display, and initiate export through the interface options.Q: When should audio-visual alarms be expected during operation?

A: Audio-visual alerts are triggered when a test cycle is completed, if any malfunction is detected, or if safety thresholds are breached. This timely warning helps ensure immediate response and secure handling of the apparatus.Q: Where can this controller be mounted or installed?

A: The controller can be mounted on a benchtop for standalone use or integrated into a panel alongside fatigue testing machines. Its standard dimensions and design fit most laboratory and industrial setups.Q: What are the benefits of the corrosion- and impact-resistant housing?

A: The robust steel and ABS housing protect the controller from harsh laboratory conditions, accidental impacts, and corrosion, thereby enhancing durability and reducing maintenance costs during long-term use.Q: How accurate are the fatigue cycle measurements?

A: The controller maintains an accuracy of 0.5%, providing reliable cycle counting and voltage measurements for fatigue tests. This ensures precise results, essential for quality control and research documentation.Q: Is the controller compatible with all fatigue testing machines?

A: Yes, the controller is designed to be compatible with most standard rotating bending fatigue testing machines, thanks to its universal size, connectivity, and mounting options.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese