- Home Page

- Company Profile

-

Our Products

- Instrumentation products

- Material Testing & System

- Stress Corrosion Cracking Testing Machine

- Impression Creep Testing Machine

- Low Velocity Drop Tower Impact Testing Machine

- Advanced Impression Creep Testing Machine

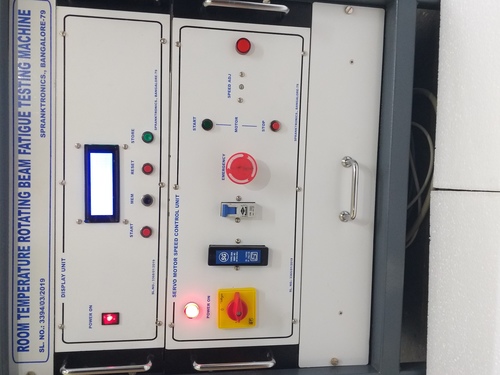

- ROTATING BENDING FATIGUE TESTING MACHINE

- Uni Axial Fatigue Testing Machine

- Constant Load Stress Corrosion Cracking Test Setup

- Rotating Bending Fatigue Testing machine controller

- High Temperature & Room Temperature Rotating Bending Fatigue Testing Machine

- Vibration Measurements & Analysis

- Sensors & Data Acquisition Systems

- Transportation & Structural Engg. Lab. Equipment

- Soil Fatigue testing Machine

- Material Testing Machines

- Contact Us

Advanced Impression Creep Testing Machine

Product Details:

- Usage & Applications Used for impression creep testing of plastic and polymer specimens in research, quality control and education

- Pressure Up to 20 kg/cm

- Accuracy 0.01 mm for displacement measurements

- Resistant Feature Corrosion resistant, thermally insulated chamber

- Product Type Advanced Impression Creep Testing Machine

- Operating Temperature Ambient to 300C

- Frequency (MHz) 50 Hz

X

Advanced Impression Creep Testing Machine Price And Quantity

- 1 Set

Advanced Impression Creep Testing Machine Product Specifications

- Overheating protection with automatic shut off

- Used for impression creep testing of plastic and polymer specimens in research, quality control and education

- 50 Hz

- Blue/White

- Up to 20 kg/cm

- Approx 180 kg

- 0.01 mm for displacement measurements

- Approx 900 x 500 x 1500 mm

- Corrosion resistant, thermally insulated chamber

- Standard laboratory size

- Advanced Impression Creep Testing Machine

- Ambient to 300C

Advanced Impression Creep Testing Machine Trade Information

- 5 Set Per Month

- 2 Week

Product Description

Capacity: 0 to100 KGs

Furnace Temperature capacity: 800 Deg C working temperature with vacuum, recommended temperature range with out vacuum is less than or equal to 500 Deg C

Indenter Diameter : 1,1.5 mm, material Tungsten carbide

Specimen Dimension : 4 to 10 mm thick, circular/square suitable to specimen platform(30 mm)

LVDT: 0 to5 mm with 1 micron resolution, Load cell :100 KG capacity

Vacuum Range: 10 pow-5 m-bar max

Stress range: 1248 MPA max using 1 mm indenter, 555 MPA using 1.5 mm indenter.

Banking on our hi-tech manufacturing facility, we are affianced in providing our clients superior quality Indentation Creep Testing Machine. This machine is manufactured with high precision to meet the set quality standards under the guidance of our deft professionals with the utilization of optimum grade components and ultra-modern technology. As the name implies, this machine is used to calculate stress rate, time and pressure in various industries. We offer this Indentation Creep Testing Machine in different technical specifications as per the demands of our clients at affordable rates.

Features:

-

Noise free operation

-

High performance

-

Rugged design

-

Long service life

Consistent and Accurate Testing

With a digital PID controller and uniform temperature distribution, this machine delivers repeatable and accurate results. Automatic data logging and a precise load application enable comprehensive research and quality control analysis of plastics and polymers.

Efficient and User-Friendly Design

Featuring a backlit LCD for clear readouts, the testing process is straightforward. The machine is equipped with safety features including overheating protection and is validated with a traceable calibration certificate for reliable operation.

Wide Application Versatility

Suitable for research institutes, educational facilities, and quality control departments, this machine tests up to three specimens simultaneously. Continuous operation capability and robust construction broaden its versatility in plastics and polymer testing.

FAQs of Advanced Impression Creep Testing Machine:

Q: How does the Advanced Impression Creep Testing Machine apply and control load during testing?

A: The machine uses a dead weight lever system with precision weights, ensuring accurate and stable application of load up to 20 kg/cm. This method allows consistent loading throughout the duration of each test.Q: What is the process for recording and monitoring test results with this machine?

A: A digital timer and load indicator, integrated with data logger functionality, automatically record all relevant test parameters. The backlit digital LCD display offers real-time readouts, and data can be retrieved for analysis and documentation.Q: When should the machine be recalibrated to maintain accuracy?

A: The machine comes with a traceable calibration certificate upon delivery. Periodic recalibration is recommended as per the manufacturers guidelines or according to laboratory quality assurance schedules to ensure measurement accuracy is maintained.Q: Where can this creep testing machine be used effectively?

A: Ideal for laboratories in research institutes, educational settings, and quality control departments, the machines standard lab size and corrosion-resistant chamber suit a range of controlled test environments.Q: What are the benefits of using a digital PID temperature controller in this equipment?

A: The digital PID controller maintains precise temperature control (1C uniformity) within the chamber, which is critical for consistent and reliable impression creep test results across the entire duration of the experiment.Q: How many specimens can be tested simultaneously?

A: The testing machine is designed to accommodate up to three specimens per test cycle, enhancing productivity and enabling comparative studies within a single operation.Q: What protection features does the machine offer during operation?

A: It is equipped with an overheating protection system that automatically shuts off the machine if unsafe temperatures are detected, safeguarding both the specimens and the equipment.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese